Lifting and transportation mechanisms

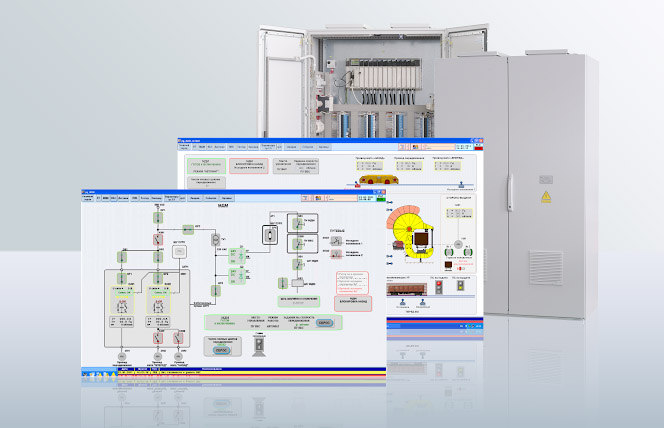

Unloading complex control system SURK

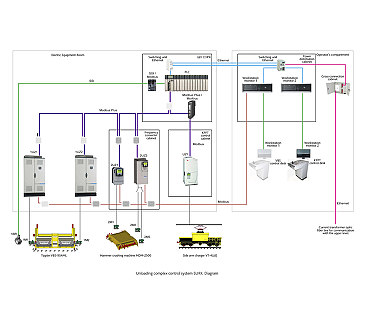

Unloading a complex control system is a large and quite complex lifting and transportation mechanism. The system is provided for control of the Ministry of communication lines park four-axle open wagons with a cargo-carrying capacity of 65...93 tons unloading process (humping and dumping), as well as for unloaded material (mainly coal or coke) crushing process control.

It provides optimal control in various modes for all mechanisms and other units of unloading complex:

- fixed side discharge car dumper VBS-93АМL;

- car pusher VT-4L(d);

- hammer crushing machine МDМ-2500;

- track and auxiliary equipment.

Technical characteristics

Supply voltage: AC single-phase 220 V, 50 Hz. Control system voltage: regulated single-phase, 220 V, 50 Hz. Control system auxiliary voltage: 24 V DC.

Application fields

SURK can be applied on approach roads of industrial enterprises, sinter plants, heating and power plants, processing plants, in quarries, etc.

SURK structure:

- control cabinet (SHU);

- workstations cabinets (SHRS);

- control desks.

Local control of machines and separate mechanisms of unloading complexes machines is carried out by means of control desks and boxes, located on the sites near machines or on the railways in the coupling area.

Functionally, the control system consists of the following devices and systems:

- programmable logic controller (PLC);

- two workstations (WS);

- unloading complex machines control panels and boxes with control and signaling units;

- field equipment (contact switches, sensors, audiovisual alarm on sites);

- unloading complex machines control cabinets with power equipment, frequency, and DC converters.

Optical switchboard cabinet SHKO is provided for connection to the upper-level control system.

Unloading a complex control system (SURK) is automated (but not automatic), i.e. involves the operation of technical control means under operator supervision and assistance.

Power switching equipment, DC, and AC drives converters are located in control cabinets.

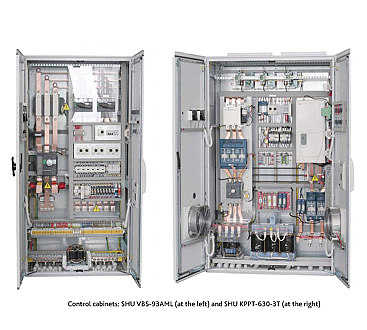

1) car dumper VBS-93АМL equipment:

- control cabinet SHU VBS-93АМL;

- frequency converters of main drive ATV71 EXS5C20N4-S50.

2) car pusher VT-4L(d) equipment:

- control cabinet SHU KPPT-630-3T

3) crushing machine МDМ-2500 equipment:

- control cabinet SHU МDМ-2500;

- crushing machine moving and rotation drives frequency converters cabinet SHPCH.

PLC, 24 V DC power supply (for sensors and signaling power supply), relay galvanic isolation of signals are located in control cabinet SHU.

Signals from control panels and boxes, control cabinets, sensors, contact switches are fed directly to control cabinet SHU SURK. Data exchange between PLC and workstations is carried out via an Ethernet network. Unloading complex machines main drives are controlled via Modbus Plus busbar.

Workstations displays, controls, and signaling units of unloading complex machines are located on the control panels PU VBS-93AML and PU KPPT-630-3T. The crushing machine is also controlled from PU VBS-93АМL (car dumper control panel).

Crushing machine control desk PU MDM:

- the crushing machine is locally controlled from PU MDM located near the machine.

Car coupler box YAUS1. Car coupler box YAUS1 enables:

- car dumping permit/prohibition;

- braking device clamping/unclamping;

- signaling on/off;

- car dumper equipment emergency shutdown;

- car pusher movement prohibition/prohibition cancellation;

- car pusher equipment emergency shutdown.

Car coupler box YAUS2. Car coupler box YAUS2 enables:

- car pusher movement prohibition/ prohibition cancellation;

- car pusher equipment emergency shutdown.

Control box YAU. Control box YAU enables:

- car dumper equipment emergency shutdown.

Documents

All documentsHow can we help you?

Please, contact us in case you have any technical queries, requests regarding customized procurement or delivery time of equipment